FIle No: 85700-35-0210206

Name of Action: Construction and Pile Drilling for Current Turbine Project

Proponent: Lester B Pearson College

Review Date(s): Nov 2, 2005

- Issues and Environmental Components

- List any issues of concern that have been or may be raised by BC Parks, other government agencies, First Nations, or the public.

2 Identify any geographic “hotspots” at or close to the proposed action (e.g., areas of high use, concentrations of facilities, wilderness conservation zones, unique landscape features).

Below are the relevant items that we are contributing to this Preliminary Assessment, the third in a series leading up to this project. If further items are provided in the next few weeks, they will be updated here:

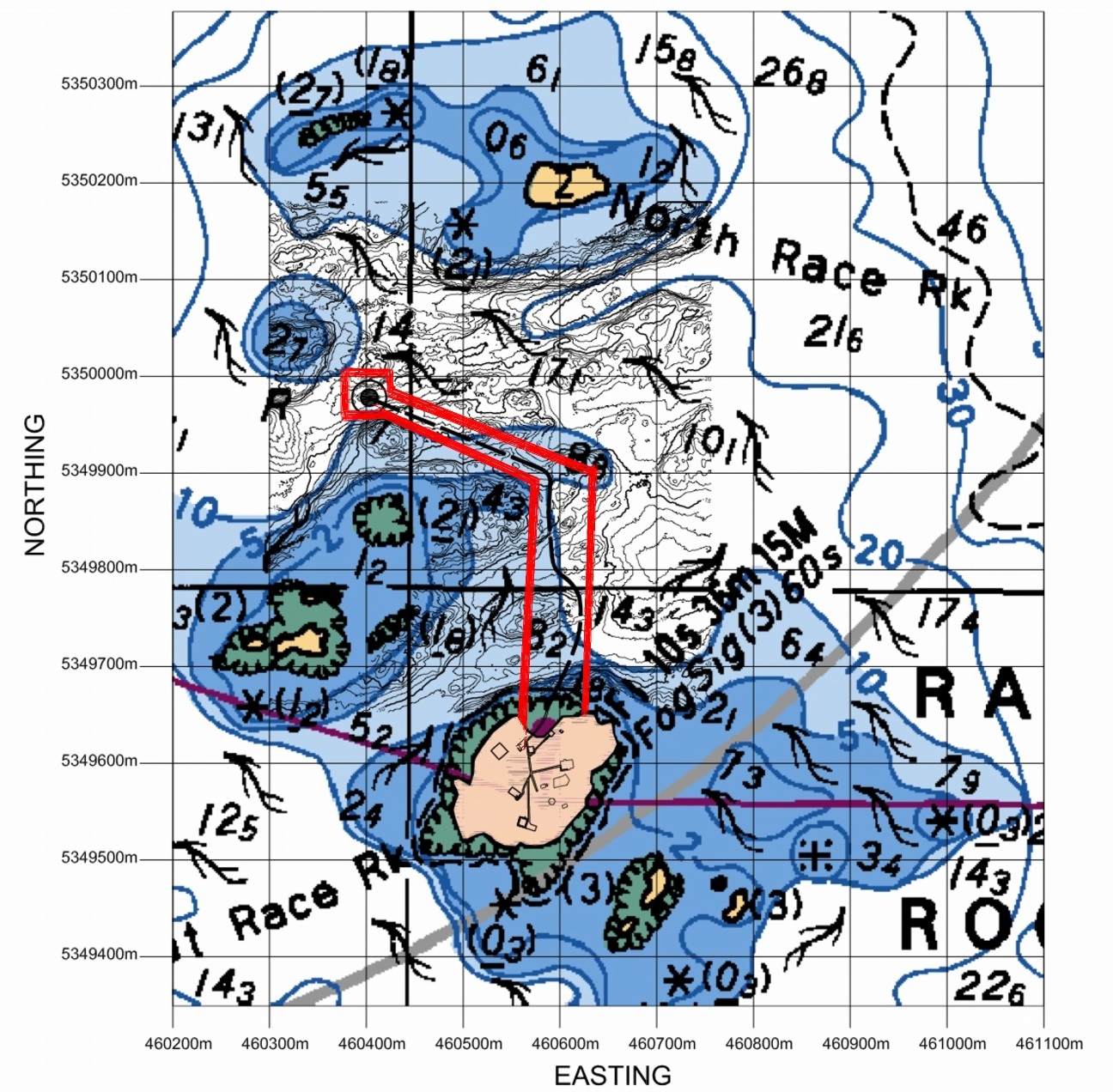

Location: The proposed location of the Tidal Current Generator Piling for the Cradle is shown below. This site was chosen after extensive testing of the current profiles in both channels with the Acoustic Doppler Current Profiler.

The red lines indicate the Pearson College permit access area..

3. Identify any important environmental, recreational, social or economic values in the area of the proposed action and/or the area surrounding the proposed action (e.g., rare or endangered species, hiking experience, midden site). Include a rationale as to why the value is considered important.

The location for the installation is in the current channel just South of North Rock, with the typical associations of organisms of the highly current swept areas of the island. Since the depth is up to 20 meters, there are few macroalgae present.

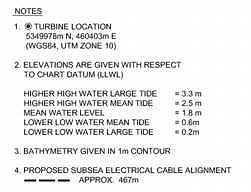

Archipelago marine has done a SIMS towed video CD . The route they took and the timing of the footage was done according to this Chart. Video taken by Pam Thuringer in the area of the chart missed by the towed video is now available from Archipelago marine

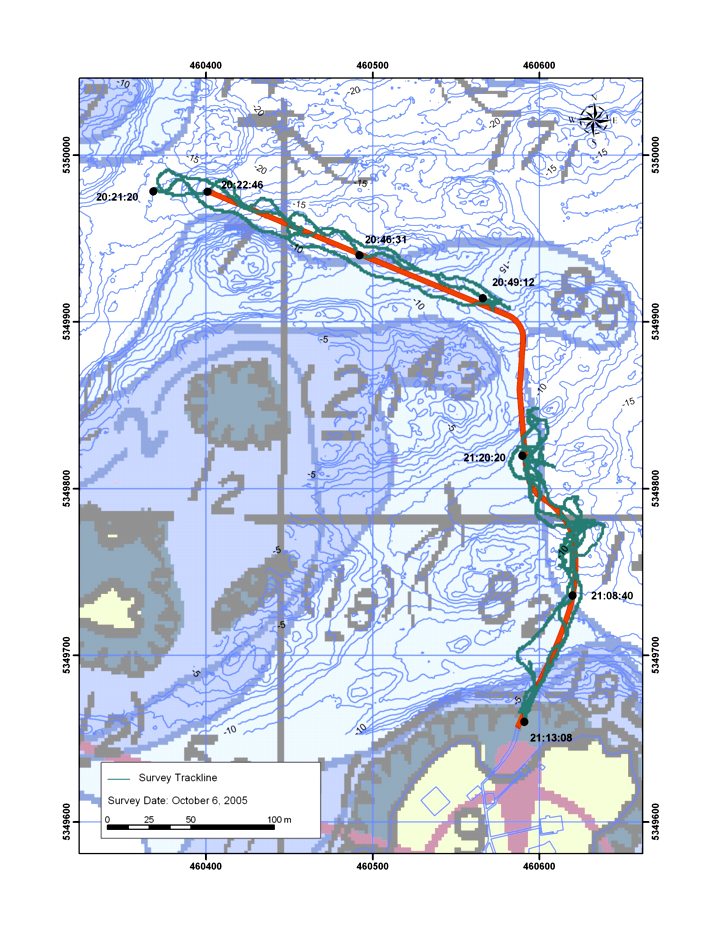

Some footage taken by the Pearson College Divers which shows the bottom fauna in the area of the turbine piling is located here:

In order to predict the best location for the installation of the tidal power generator, an ADCP ( Acoustic Doppler Current Profiler) supplied by ASL Environmental Sciences was deployed. This instrument will collect current regime information for a period of one month. Rita Santos did the video and Angie Karlsen helped Chris Blondeau lift and position the concrete weights used to secure the device on the sea floor..

For an idea of the general patterns of organism distribution, the two clips below were taken from the video which was filmed at the location of the ADCP research at Station2:

- The current swept area is covered with the typical Metridium senile, Balanaus nubilus, Strongylocentrotus franciscanis community.

- The ADCP instrument was installed for a month in this location in the spring of 2005

| Preliminary Screen Checklist (partial)

C. Level 1 report should recommend appropriate times and methods for construction to ensure birds /wildlifeimpacts are kept to a minimum. Date of work: The installation in November is timed after the nesting and seal pupping season and in the time of the year when the Sea Lions have returned but are concentrated in the area to the East of the docks, on South Rock and on Middle and West Island. The closest population that may be disturbed by the drilling is on North Rock, and part of Middle Rock. In the past that population frequently comes and goes probably because of the fall schedule of blasting by DND . |

||||||||||||||||||||||||||||||||||||

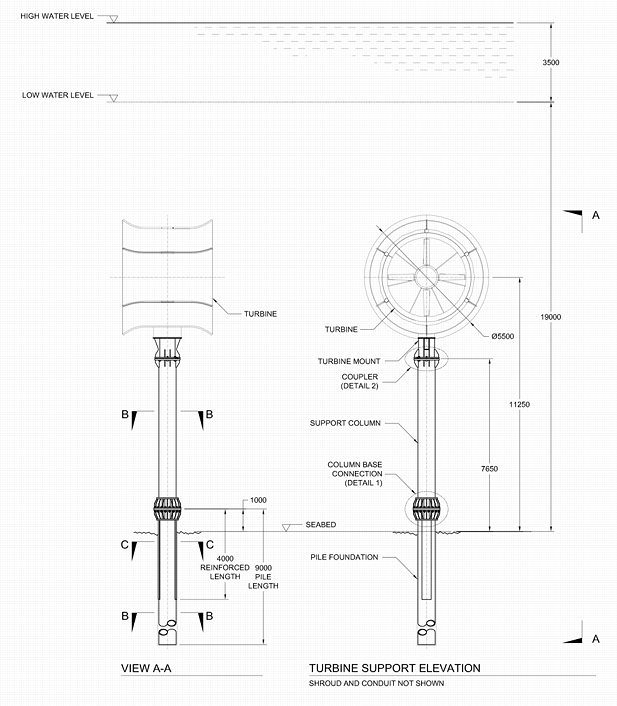

| Construction Method: We have been advised that a contract has been let by Clean Current for the drilling and installation of the piling to bear the generator to:

Fraser River Pile & Dredge Ltd. (FRPD) 1830 River DriveNew Westminster, B.C. V3M 2A8 Tel: (604) 528-9333 (Project manager Rick Gillis) The attached .pdf file.. Construction Drilling provides the details of this phase of the project. The amount of oil consumed in the drilling operation is approximately 5 gallons /hr. For a drilling depth of 8 m, the operation should take 4-5 hours. The drilling operation will not produce an oil slick. In the event of a spill FRPD, will employ their standard method of deploying containment booms and pads to contain the oil. Due to the challenging conditions in this area, FRPD will have additional booms and pads on board. |

||||||||||||||||||||||||||||||||||||

| Equipment Island Tug operates a large fleet of tugs and barges including one self-propelled cable layer. The principal method of cable handling utilizes one of two powered self-breaking drums. Reel number 1 has a capacity for 80,000 feet of 2-inch diameter cable with a break holding capacity of 200 tons. Reel number 2 has a capacity for 30,000 feet of 2-inch diameter cable with a break holding capacity of 100 tons. Procedure of Cable Laying – General Reel number 2 is mounted aboard the cable layer, Georgia Transporter. Cable is transferred from shore storage reels to the ship-mounted reel and transported to the site. Cable is taken ashore at the cable shore-end via a bow mounted adjustable ramp. A bow mounted cable chute is used to deploy the cable while the Georgia Transporter is towed astern. Two GPS systems monitor the surface position and provide feedback via digital charts. Track corrections are implemented through a variety of methods using the Ship’s power, directing the towing vessel or employing side boats. For shallow water lays, the cable tension is not monitored by equipment but by the angle off the bow, with lay and reel speeds corrected as necessary. For deep-water lays, the cable tension is monitored with on deck tension monitoring equipment such as linear tension devices or load cells. Cable weights and water depth information are pre plotted along a planned track in order to adjust for the intended tension at given positions. Reel number 1 is mounted aboard one of Island’s flat deck barges and used in the same manner as the description above, with the exception that the barge will start and finish on four point moorings. Island Tug And Barge Ltd. |

||||||||||||||||||||||||||||||||||||

Piling Construction:

|

||||||||||||||||||||||||||||||||||||